The photo above was taken shortly after BOWDOIN’s June relaunching, after a winter in Lyman-Morse’s shop being re-topped. The others that follow show details that intrigued me as I wandered around the project while the crew was at lunch. I hope you enjoy looking at them and that you come away with a deeper understanding of wooden ship repair.

A humidifier at work all winter under a skirt of plastic kept BOWDOIN’s hull planking from drying out in the heated shed.

The bulwarks, sheerstrakes, and several planks below them needed replacing, along with the entire deck and top timbers—all in the name of re-topping. Planking is oak; top timbers are locust.

White pine covering boards fit down over the top timbers and fasten to the sheer strakes and deck beams. Several deck beams (of oak) were renewed.

The covering boards are butted together and a white pine stopwater makes the joint watertight. Wedges, also of pine, do the same at each of the top timbers.

Scupper strakes run the length of the main deck in order to meet and match the sheer strakes of the raised foredeck. Above this level, the bulwark planking is thinner—all the way up to the railcap.

This is the so-called breakbeam where the main deck and the raised foredeck meet. It is rabbeted, to form a landing for the fore deck planking, while the planking of the main deck, laid earlier, is sandwiched between this timber and the lower breakbeam that lies directly under it.

The foremast partner, like the upper breakbeam (left), is new. But the lodging knees that brace it are being reused.

This shows how the covering board gets notched to make a landing for the nib ends of the decking.

BOWDOIN’s deck is laid before any cabins are landed, so the portions of the seams that the cabins cover (which become inaccessible for subsequent caulking) are kept watertight by the pine wedges shown here. Cotton followed by oakum followed by black seam compound keeps the rest of the deck watertight.

One of the scarfs where two sections of rail cap join. Small areas of the edges have been left square for ease of clamping, and for fairing the two rail cap sections together after they’re fastened to each other.

Looking aft, with the white pine decking partly laid and the rail caps partly installed.

Looking forward shortly after BOWDOIN’s June 6th re-launching—and after sanding has cleaned up the seam compound overspread. Very evident here are the nibbed ends of the deck planks, the rabbeted upper breakbeam, and raised foredeck.

This shows how the thinner bulwark planking creates a recessed waist for the vessel, and how the stout rail cap creates the handsome sheerline that invites the eye. The rectangular cutouts are scuppers that drain the deck of any water that comes aboard. The waist (foreground) has been bored and trimmed for a chock.

Carved scrolls surround the hawsepipes. A lovely carved-in name (BOWDOIN) will soon follow.

The schooner BOWDOIN in 2011 at her Castine homeport where she berths next to Maine Maritime Academy’s big training vessel STATE OF MAINE.

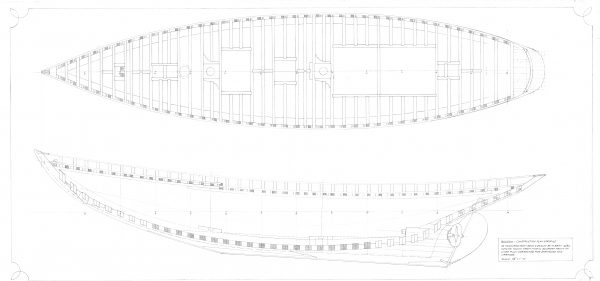

Back in 1980, soon after BOWDOIN was hauled out at the Maine Maritime Museum in Bath and before John Nugent tore out and replaced any of her original structure, I measured the deck and hull framing and drew this construction plan. For OCH members interested in how the vessel was built, here’s an opportunity. (The original construction drawings by desiner William H. Hand have never surfaced, but the arrangement plan did and is included here as excerpted from the

. . . sign up to the right to get immediate access to this full post,

plus you'll get 10 of our best videos for free.

Get Free Videos& Learn More Join Now!!for Full Access Members Sign In

tom laverty says:

will Bowdoin be at the Mystic Seaport this weedend?

Rick Jacks says:

Thank you Maynard. Your comments on the details of projects such as this are indeed priceless.

patrick marks says:

Great job. Very informative.

David Chapman says:

My mother’s uncle, Jack Crowell, served as Admiral MacMillan’s skipper on a number of the trips to the Arctic. I grew up hearing stories of the Bowdoin. (In fact, my mother and my nephew were with Jack on Kimball Island the night he died.) In 1997 Bowdoin was in Boston for the bicentennial of Old Ironsides. Although she was not open to the public, when I told Andy Chase, who was at that time Maine Maritime’s captain, of the family connection he was gracious enough to invite me, my wife and our son on board for a tour below decks. This video is fascinating. It is wonderful that the Bowdoin continues to sail. Thank you.

Conbert Benneck says:

I have a Boucher Company model of the Bowdoin that was sold in the 1920’s. The hull was built for Boucher by the Acushnet Company.

I bought the model from another boy at Conservatory Lake in Central Park, NYC, about 1930.

The model has sailed internationally, in Paris at the Jardin de Luxemboug; in Communist waters in the Adriatic, when we cruised there; and in Germany on the Chiemsee.

It’s still going strong awaiting the next generation of grandchildren who can enjoy sailing it too.

Edwin Spears says:

Awesome!

Randy Pickelmann says:

How are the decks finished? Are they left natural or are they protected with oil?

Maynard Bray says:

Hi Randy, I visited Bowdoin today and learned that the plan is to leave the pine decks bare, without any treatment other than periodic salt water wash downs. The white pine is all heartwood, and its grain is vertical, so it should last OK—just as the old time decks did.