For those of you just tuning in to Eric Blake’s weekly walkabouts, the boats he describes being built new in Brooklin Boat Yard’s main shop are a pair of 47’ daysailers designed originally by Bob Stephens and later tweaked by Eric, Keith Dibble, and others here at the yard. (Two others of the same design, LENA and LARK, were built here earlier.) The other new construction for this winter is the 70’ Dieter Empacher-designed SONNY—a duplicate of an earlier sloop of the same name that the owner donated to Maine Maritime Academy. This will be her replacement—for the very same owner. The place is booming!

Now for Eric’s tour in his own words:

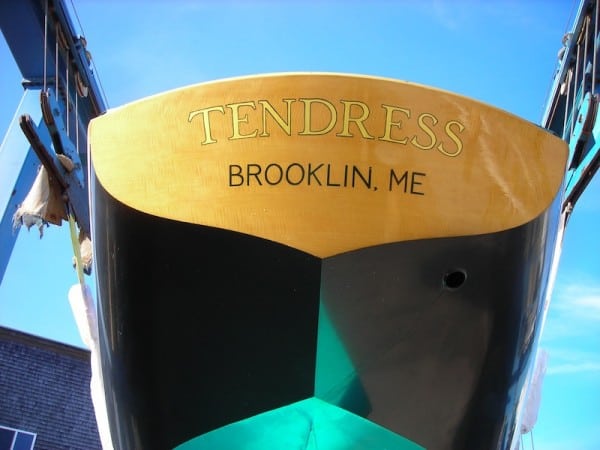

One of the best things about running outside to the stockroom to get a box of #10 x 1 1/4″ bronze wood screws is what you might find hanging in the yard’s Travelift slings. Those of you who have followed my posts know by now that I have a few favorites. TENDRESS is one of my top five. She was designed and built here just before I started about 10 yers ago. The design is called a Babson Island 35, and was drawn for a customer who loved the Center Harbor 31 design but wanted something just a little bit different. Her beauty mesmerizes me. The exterior trim (cabin sides, coamings, toerails, etc.) is done in an African maple called Anegre and is heavily figured with tiger stripes. Take a close look at the grain in the transom. The way that the sun catches the figure in the wood is really stunning. In the low morning light, all this brightwork stands out unlike anything I have ever seen before.

One of the best things about running outside to the stockroom to get a box of #10 x 1 1/4″ bronze wood screws is what you might find hanging in the yard’s Travelift slings. Those of you who have followed my posts know by now that I have a few favorites. TENDRESS is one of my top five. She was designed and built here just before I started about 10 yers ago. The design is called a Babson Island 35, and was drawn for a customer who loved the Center Harbor 31 design but wanted something just a little bit different. Her beauty mesmerizes me. The exterior trim (cabin sides, coamings, toerails, etc.) is done in an African maple called Anegre and is heavily figured with tiger stripes. Take a close look at the grain in the transom. The way that the sun catches the figure in the wood is really stunning. In the low morning light, all this brightwork stands out unlike anything I have ever seen before.

. . . sign up to the right to get immediate access to this full post,

plus you'll get 10 of our best videos for free.

Get Free Videos& Learn More Join Now!!for Full Access Members Sign In

Anne Bryant says:

I have the biggest crush on Quest. Ssshhh… don’t tell MIMI ROSE.

Brian Crow says:

Nicely done! Thanks Eric…I really like the across the beam tool tray, keeping tools needed for the job out of the way of the people working, and making a cleaner job. When I was doing re-planking/fastening/caulking jobs, I had a little shopping cart filled with the nessary tools and stuff, and pushed it along with me as I went; it sure made the job easier!

Dennis Dunn says:

Eric:

Would you mind answering a few questions about the veneers used for the cabin sides in the 47’s? In particular,

1) Do you resaw dimensional lumber to get your veneers? How wide are these veneers? I assume there not as wide as the cabin sides are high, so how do you “hide” the glue line?

2) In gluing 3/16″ Mahog. veneer to the inside of the 5/8″ Teak cabin sides, are you not concerned about the differences in swelling characteristics between the two woods? I understand how this works on the back of the cabin because the veneers are glued to dimensionally stable plywood that prevents the veneers from moving.

Thanks.

-Denny

dunn@cse.psu.edu

Steve Stone says:

Hi Dennis. Eric’s on holiday for some much needed R&R with family, but I’m sure he’ll reply when he get’s back.

Eric Blake says:

Denny, sorry for the delay in my response. The early birth of my daughter has been keeping me busy. We have the veneer resawn from our wood supplier. 1/4″” thick veneer is resawn with a large bandsaw up to 14″ wide. We then run it through a thickness sanding machine here at the yard to finish it at 3/16″ sanded to 120 grit. On a cabin this size 14″ is plenty wide to do the job. If wider stock is required the glue seam would be “hidden” by making a good fit and matching the grain of two separate pieces. As for laminating mahogany to teak, your concerns are valid about making a sandwich of disimilar woods. The wood we get is extremely high quality, quater sawn, and at an ideal moisture content of about 7%. The veneer is applied with a vacuum bag insuring no voids. The cabin is then sealed inside and out with many coats of sealer and varnish. Good quality Teak and Mahogany behave very similar, and we have never had a problem. I am a fan of building cabin sides this way even if the same species of wood is used inside and out. Laminating two layers will always be stronger and more stable than solid wood house sides.

Hope this helps,

Eric

Dennis Dunn says:

Eric:

Thanks for the very informative reply and congratulations on your new baby. I’m currently restoring an old yawl whose cabin sides are badly checked. Replacing them with dimensional lumber would be cost prohibitive, so I was faced with having to fill and paint them. Based on your comments, I’m now considering replacing them with plywood + H. Mahogany veneer on both faces. Still expensive, I’m sure, but better in the long run.

-Denny

Dennis Dunn says:

Eric:

I apologize in advance if these extended questions are not appropriate for this blog.

I understand now why you can bond H. Mahogany to Teak. Because the veneers are quarter sawn, the tangential direction is in the thickness dimension where differences in dimensional changes don’t stress the bond line. In the radial direction, the dimensional changes for Mahog and Teak are quite similar.

I am also curious as to what adhesive you use for laminating – epoxy, resorcinol , or something else? Epoxy seems to be more versatile but I’ve read that delamination can be a problem, especially in cyclic wet/dry environments or where the laminate is exposed to direct sunlight (low glass transition temp.).

Finally, would you be will to share the name of you wood supplier? Thanks.

-Denny

Eric Blake says:

Denny,

Having the solid teak house sides split after dropping a 55 square meter sloop off a large wave around Cape Cod before, this is a detail I have come to trust and use on all the boats I have built since even if the wood inside and out is the same species. It is strong and stable. All of the structural laminating we do at the Brooklin Boatyard is done using West Systems epoxy. They work very closely with us to develop better ways of building with wood epoxy. They are always very engauged in what we are doing and how they can make their products better for us. I cannot say enough about them. Failures in wood epoxy come from misuse. Typically glueing together pieces that are thick, damp, and unstable. When applying a veneer it is best to use a vacuum bag to insure that you have no voids, but even adequate clamping pressure works just as well. Wood that is no thicker than 2″, has a moisture content of no more than 12%, that is properly prepped and clamped is how epoxy works best. As for our wood supplier, we get wood from all over but our main supplier is Americas’ Wood Company in Washington Me. They deliver every Thursday and they supply us with thousands of board feet of wood a year. They are good people.

Carolyn Studley says:

Enjoyed the tour, Trinket

Gregory Phillips says:

Thanks for the tour, Eric. These tours keep me out of the shop and out of your way!!

Eric Blake says:

Please come by anytime Greg. It’s people stopping by that keeps us on our toes.

Anne Bray says:

So great to see what is happening at BBY and understanding the process. Thanks Eric.