Preview: FRANCIS LEE: The Ultimate Sailing Machine, Part 2 – The Boat Tour

* * *

OffCenterHarbor.com is a membership website with over 1,000 videos and articles

on boat handling, repairs, maintenance, boat building, dream boats and more.

Sign up above to learn more, and get 10 of our best videos.

* * *

November 11, 2015

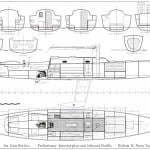

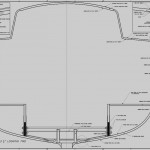

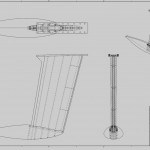

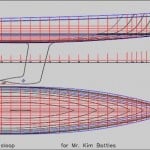

Email this Video to a FriendEric’s tour above and below decks shows Bob Perry’s sharpest pencil at work in the design of FRANCIS LEE.

Get Free Videos Start Free Trial Members Sign In

Comments, Thoughts or Suggestions?You can leave a comment or question for OCH and members below. Here are the comments so far…

Leave a Comment

You must be logged in to post a comment.

4 Responses So Far to “FRANCIS LEE: The Ultimate Sailing Machine, Part 2 – The Boat Tour”

or …

Michael Seibert says:

Beautiful Boat and a good video, but you asked for suggestions, so here goes:

I would love to see a video featuring a sailboat that I could possibly afford and build: 30 feet (or less), classic looks, modern sail plan, keel and rudder, and competitive is racing without being uncomfortable to sail with a small crew and cruise for a week or two.

Would love to hear suggestions on existing designs that fit the bill.

Larry Morris says:

How about a Thunderbird. 28′. Plywood construction great sailing boat for the money.

Bruce Abrahams says:

A beautiful boat. I have a 28″ double ender in poor condition. Watching this video has been inspiring. I now will not put in lifelines. My boat has a push pit and pulpit, but no lifelines. Now After seeing this and some boats in the background I see I don’t have to ruin the lines by adding them. Thanks again for sharing.

Kim Bottles says:

Bruce, what design is your vessel?